Electrostatic Solution for Ink Splashing in Printing Machines

Customer Pain Points:

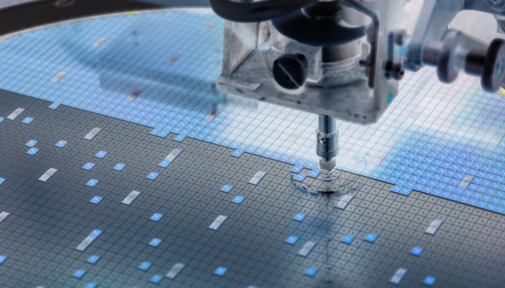

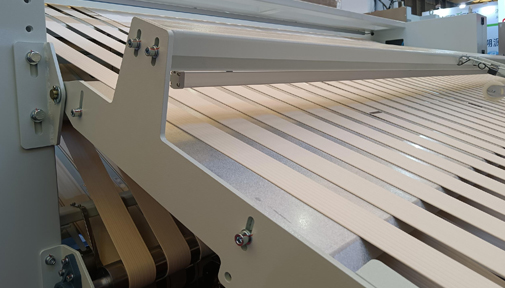

Due to high-speed friction between materials and rollers during printing, the materials become charged. After passing through the ink tank and transfer roller, the ink is not dry, causing the static electricity to disperse the ink and result in unqualified printing quality.

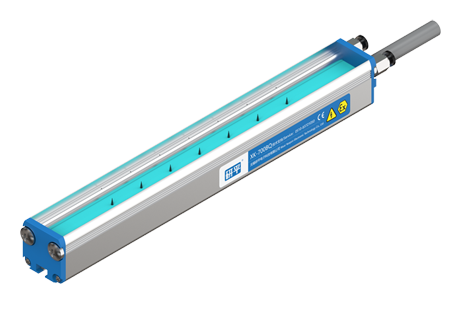

Solution:

Use electrostatic elimination equipment to eliminate static electricity after transfer and before entering the oven, ensuring that static electricity does not affect the undried ink.